Have you ever visited a Bedrock Quartz showroom and left wondering how an enormous block of stone ultimately becomes a luxury countertop in a modern home? Welcome to the world of stone countertop fabrication. It is something we think about all the time.

We obviously know the process inside and out. But we also understand that many of our customers don’t. Some are curious enough to ask. Others are so interested in the details one would think they are looking to become professional stonecutters.

Because we appreciate our customers so much, we want to offer a little insight into the process. We can’t give you all the details in a single blog post. But we can offer a general idea of how we get from a large block of stone to a beautifully installed countertop.

1. The Stones Are Quarried

The first step in the process has nothing to do with fabricators at all. It is the quarrying step. Quarry owners cut large blocks of marble, granite, and quartzite and prepare them for shipping. They may be reduced to smaller blocks prior to shipping or are shipped full size.

Either way, the larger blocks are reduced in size before being distributed to companies like Bedrock Quartz. From there, it’s the fabricator’s job to work with the homeowner on creating the perfect countertop slabs.

2. Materials Are Inspected and Selected

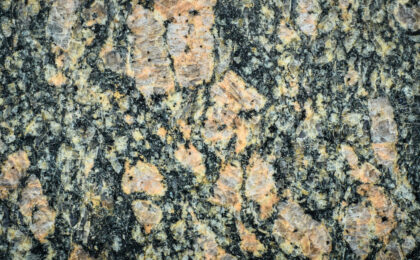

Before we make the materials available to customers, we personally inspect each slab for quality, consistency, etc. We want only the best quality for our customers. Once we are satisfied, we display a variety of slabs in our showrooms.

The next step involves a secondary inspection, this time with the customer. We show each customer a nice selection of granite, marble, and quartzite. We invite the customer to look at each slab closely. What are they looking for? Overall quality, unique features, and anything they might perceive as a flaw. We want each customer to be absolutely thrilled with the final choice, which is why we place so much emphasis on inspections.

Once the customer has selected a slab, it is time for our fabricators to go to work. Each member of the team contributes something different.

3. It’s On to Digital Templating

Before a single cut is made, a member of the fabrication team will create a precise digital template. This involves visiting the customer’s home to measure cabinets, walls, sinks, appliances, and everything else that affects the installation space. It’s critical that these measurements be absolutely perfect because once a slab is cut, there is no going back.

4. Laying Out the Slabs

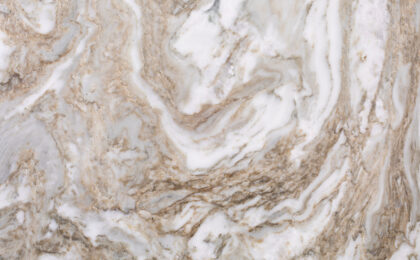

A finished template lays the groundwork for the next step: laying out the slabs. The fabrication team will use digital tools to lay out veining and movement to achieve the customer’s preferred look. Seams will also be placed to minimize visual disturbances.

5. Cutting and Shaping

By the time we get to the cutting and shaping stage, all the previous plans have been firmly laid. There’s no going back once the first cut is made. Stone slabs are cut with precision CNC machinery accurate to the millimeter. Edges are also shaped according to the customer’s profile preferences.

A slab is cleaned and polished after cutting. How it is polished is determined by the finished look the customer is after. From high gloss to matte, a variety of finishes are possible.

6. Delivery and Installation

The final step in turning a large block of stone into a countertop is delivery and installation. When installers leave a customer’s home, the transformation is complete. It’s truly remarkable, by the way.