2

SELECTING YOUR MATERIAL

Selecting the appropriate material is arguably the most challenging step in the purchasing process. Bedrock Quartz has curated an extensive, in stock inventory at competitive prices. Alternatively, you have the flexibility to choose materials from your preferred vendors, or we can provide a list of local material suppliers. To expedite the process, it helps if you have paint, flooring, and cabinet samples to facilitate decision-making. And if you’re unsure, your Bedrock Quartz Stone Consultant can help you decide.

CHOOSING FROM A SAMPLE

Bedrock Quartz’s in stock colors typically exhibit greater uniformity and consistency in their hues. Nevertheless, it’s important to note that stone samples represent the product and display only the type of material found within that specific range of stone. Color variation in stone is typical, and an exact match to samples cannot be guaranteed.

LABOR AND MATERIAL COST

- • Labor costs required to handle, fabricate, and install slabs are around 60 to 80% of the project cost.

- • Most labor costs will remain the same regardless of your chosen material.

- • Opting for exotic and porcelain materials may escalate expenses due to shipping, quarrying, rarity, and the country of origin. Moreover, using rare materials might pose challenges regarding workability and durability compared to the stone options available in the Bedrock Quartz in stock selection.

- • Typically, the greater the pattern in the material, the higher the cost.

PURCHASING A SLAB

-

Slab materials are priced in two ways:

- • By the square foot – You pay for what you use

- • By the Slab – This is any custom slab you select from a slab yard

While our Square Foot Stock Program is generally the most budget-friendly and simple option, we are happy to work with materials you select from other slab suppliers. Regardless of whether we stock it, we look forward to updating your project with the stone that will fulfill your vision.

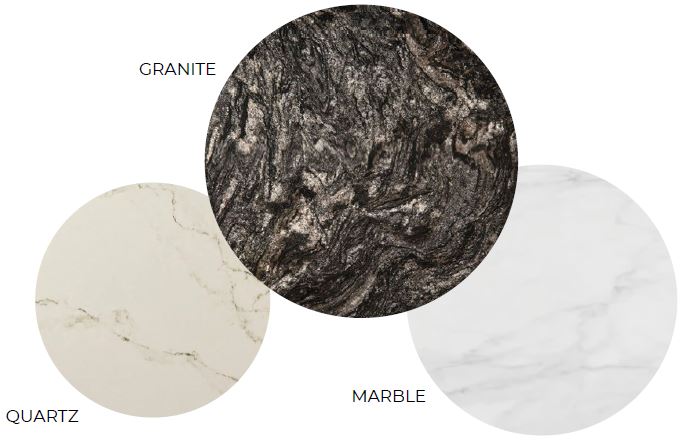

TWO TYPES OF SLAB MATERIAL

- • Natural or quarried stone is cut, sliced, and polished from the mountain. Examples include Granite, Quartzite, Marble, Travertine, and Soapstone.

- • Man-made stone is processed in a factory. Examples include Engineered Stone (Quartz) and Porcelain Slab.

TYPES OF SLAB MATERIAL FINISHES

- • Polished is the most common type of finish because it’s easy to clean and maintain.

- • Honed has a matte finish and does not reflect light as well.

- • Leathered has a unique, textured finish.

- • Granite is the most common natural stone used for countertops, followed by quartzite.

- • The average slab size is 115” x 70” but will vary from color to color.

- • Granite comes in many different types, each composed of different natural materials and properties.

- • Granite will have varying levels of maintenance and discoloration/staining susceptibility.

- • Granite is scratch-resistant and has an extremely hard surface.

- • Granite is heat resistant and unlikely to burn or scorch. However, thermal shock or cracks may occur if the countertop is subject to extreme temperature changes, so we recommend using heat-resistant pads or trivets for added protection.

- • Every natural stone possesses distinct characteristics, including variations in background color, distribution of veining, and veining patterns. Fissures and pitting are inherent attributes in granite and should be viewed as natural occurrences rather than defects. Importantly, these features do not impact the performance of granite.

- • Quartzite is dense and harder than most granites, offering unique aesthetics.

- • Quartzite predominantly comprises quartz crystals, usually more than 90% by volume. The high quartz content gives it its characteristic hardness and durability.

- • Quartzite comes in various colors: white, gray, pink, red, yellow, green, and even blue. Impurities and mineral content present influence the color during its formation.

- • Quartzite is resistant to chemical weathering, making it suitable for outdoor applications and ensuring its long-term durability in various climates.

- While quartzite shares some similarities with quartz-rich sandstone and other rocks, it has distinct properties resulting from its metamorphic processes.

- • Quartz is very popular, with many colors often imitating natural stone.

- • Quartz comprises approximately 93% stone aggregates and 7% polyester resin by weight and is pressed into slabs.

- • Seams and shading variation may be more visible with Quartz products than other products.

- • Quartz is not UV stable and will fade with direct sunlight and should not be used outdoors.

- • Marble has a unique color and appearance.

- • Marble proves to be an excellent option for backsplashes and areas with lower foot traffic that aren’t heavily involved in food preparation.

- • Marble can be used in a kitchen; however, the likelihood of marble staining and scratching is much greater than with granite.