Companies like Bedrock Quartz speak of quartz countertops as being stone products. We speak about them alongside granite and marble. But in reality, it’s not as though manufacturers are cutting up huge chunks of quartz into smaller pieces that can be fashioned into countertops. A quartz countertop is really an engineered product.

Being engineered doesn’t make it any less durable or resilient than natural stone. In fact, quartz countertops are just as tough as granite and marble. The reason they are engineered is simple: the way quartz is harvested from the environment makes it impossible to come up with solid pieces big enough to make full countertops.

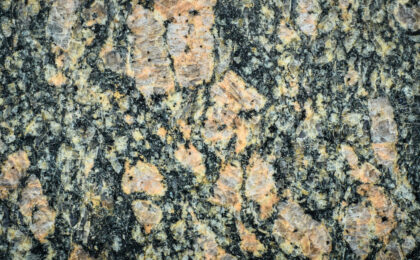

Quartz Is a Mineral

It is important to understand that quartz is a mineral. It comes out of the Earth. It is actually a mineral that is made up mostly of silicon dioxide, which can be found most plentifully in sand. But if you can picture a vast beach of sand in all its glory, you can better understand why quartz countertops need to be engineered.

Even so, quartz is a natural material. It is also durable and resilient. Manufacturers take quartz and combine it with other materials to create solid pieces of engineered ‘stone’ that can be fashioned into any number of objects. We just happen to prefer it for countertops.

Mineral and Resins

A typical quartz countertop consists of anywhere between 80% and 95% quartz mineral. But again, think of sand. You could load sand into a form, compress it, let it dry, and then remove the form. The compressed sand would maintain its shape so long as nothing disturbed it. But try to place it on top of the cabinets in your kitchen and it will fall apart.

To create a quartz countertop, manufacturers mix quartz minerals with polyester resins. The resins do several things. First and foremost, they act as a binder that keeps the minerals together; the binder prevents the actual quartz from separating.

Second, the resins give a finished countertop additional rigidity and strength. Polyester resins are heat resistant, stain resistant, resistant to chips and scratches, and less likely to discolor over time. Speaking of discoloration, the polyester resins added to quartz to make countertops offer a third benefit: aesthetic choice.

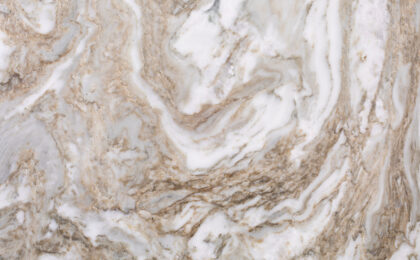

Put another way, resins can be dyed with virtually any color. That means homeowners have color choices for their quartz countertops. From a concrete gray to a beautiful linen to a soft blue, the choices really are limitless.

Nothing Too Crazy

Manufacturers try to stay away from anything considered too crazy for the kitchen. After all, most people who choose quartz countertops appreciate the look of natural stone. But still, nothing stops a manufacturer from creating a unique and over-the-top look if that is what the customer wants.

If you wanted purple and pink countertops and you could find a manufacturer willing to make them, it’s doable. That’s one of the many benefits of working with an engineered product. It is possible to create the exact look the customer wants.

Quartz Countertops are Engineered to Be Strong

The last thing we want you to know about quartz countertops is that they are engineered to be strong. Manufacturers are fully cognizant of the fact that homeowners put a lot of money into their kitchens. They expect their kitchens to be up to the task.

Quartz countertops, though engineered products are every bit as durable and resilient as granite and marble. They are also just as beautiful. We hope you will consider quartz as you look around for new countertops. And here in Utah, Bedrock Quartz is the place to go.