As the top stone fabricator in the state, precision, efficiency, and customer satisfaction are paramount. Enter Slabsmith, a revolutionary tool that has transformed how we work with natural and engineered stone slabs. For an added cost, this advanced visualization software solution can streamline the entire process of selecting, cutting, and laying out your stone slabs, offering unmatched accuracy for you and your design. n

What is Slabsmith?

Slabsmith is digital imaging and layout software designed for the stone industry to create high-resolution images of stone slabs to help visualize and plan the cutting process for custom countertops. It captures precise measurements and images to design and optimize the layout for cutting.

How Slabsmith Works

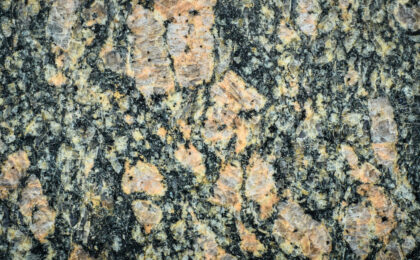

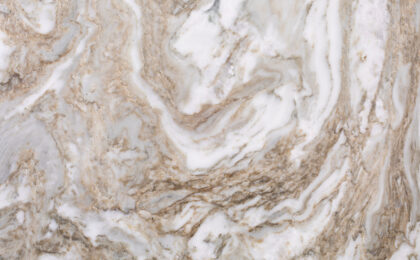

- Slab Imaging: The process begins with the slab being photographed using a specialized setup that captures every detail, including the color, texture, and veining of the stone. The resulting image is then imported into the Slabsmith software.

- Digital Slab Layout: Our fabricators can begin the layout process once the image is in the system. This involves planning how to cut the slab to maximize yield, minimize waste, and ensure that the most visually appealing parts of the stone are utilized. Slabsmith provides precise adjustments, allowing fabricators to rotate, mirror, and position templates on the slab image to achieve the best possible layout.

- Customer Approval: One of Slabsmith’s standout features is its ability to generate realistic previews of the final product. You’ll get an email from us to see how your countertops, tiles, or other stone features will look once fabricated, complete with the natural veining and patterns of the stone. This capability dramatically enhances your satisfaction, as you’ll know what to expect. For an additional cost, you can come into our office and sit with a programmer to customize your layout even more.

- Optimized Cutting: After the layout is finalized and approved, the software generates cutting instructions sent to CNC (Computer Numerical Control) machines. This ensures the cuts are made with millimeter precision, ensuring the final product is beautiful and efficient.

By minimizing waste and optimizing the use of each slab, Slabsmith contributes to a more sustainable fabrication process. Less material waste means fewer resources are consumed, making the industry more environmentally friendly.

Slabsmith has transformed the stone fabrication industry with its advanced tool that boosts precision, efficiency, and customer satisfaction. Experience the benefits of this cutting-edge visualization technology and choose the perfect stone slab for your dream kitchen by visiting bedrockquartz.com or any of our seven showrooms in Utah today.