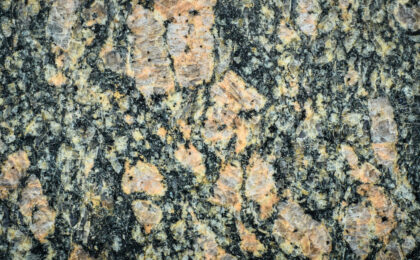

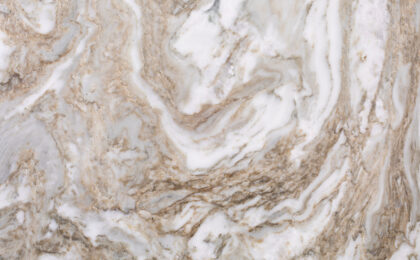

Granite, marble, and quartzite are all fantastic countertop materials Bedrock Quartz customers love. But if you are looking for something just as beautiful but a little bit more durable, quartz might be what you’re after. Quartz countertops are manufactured rather than being cut from slabs of stone. In fact, how quartz countertops are made is actually quite fascinating.

Why They Are Manufactured

Before getting into the actual process, let us discuss why quartz countertops are manufactured rather than quarried. It goes back to the quartz itself. Quartz occurs naturally in sandstone and silica sand. It occurs as small grains that do not bond together very well. Therefore, nature doesn’t provide large slabs of quartz we can mine like marble and granite.

Nature does combine quartz grains and sandstone to create quartzite through a metamorphic process. But the grains that go into quartz countertops are harvested from silica sand. They need some help binding together. That’s what the manufacturing process is all about.

Material Selection

Manufacturing begins with material selection. Manufacturers obviously need natural quartz crystals to get started. They crush the crystals into small particles that ultimately makeup 90-95% of the finished product. Along with the quartz, manufacturers also need:

- Resins and polymers to bind the quartz together.

- Pigments to add color and pattern variations.

- Other additives that create unique aesthetic effects.

With the exception of the quartz itself, manufacturers will carefully select their materials with an eye on creating a unique product. The availability of so many pigments, resins, polymers, and additives dictates that quartz countertops can be manufactured to create an endless number of possibilities.

Mixing, Blending, and Molding

After carefully selecting materials and measuring them proportionally, everything is thrown into the proverbial pot and mixed up. Materials are blended as thoroughly as possible before the next step. Incidentally, the exact ratios of each material vary depending on what a manufacturer wants to achieve.

Blending the materials creates a substance that feels a lot like wet sand. The substance is then poured into molds to create slabs. And just like manufacturers can vary ingredients, they can also vary slab size and shape.

Turning Molds Into Countertops

If manufacturers poured the combined ingredients into a mold and then just let it sit, the resulting product would not be suitable as a countertop. So to finish things off, the mold needs to be subjected to two things:

- Pressure – The mold and its contents are subjected to pressure that can be in the neighborhood of 25,000 metric tons. This compresses the mixture while simultaneously removing air. The end result is a dense quartz material.

- Vibration – Even while the mold is under pressure, it is rapidly vibrated back and forth to encourage air elimination. You wind up with a finished product boasting a smooth and consistent texture throughout.

Curing follows the compression process. Slabs are heated at temperatures of up to 195°F for 35-45 minutes. Why do slabs need curing? To strengthen the bonds between the quartz grains and the resin they are embedded in. Applying heat is the last step in turning those blended ingredients into a solid surface.

Properly cooled slabs undergo a final processing to remove excess material and standard slab size. The slabs are then ready for sale as countertops.

Are you curious about quartz countertops? Pay a visit to any Bedrock Quartz showroom and take a look for yourself. We are confident that you will be amazed by the beauty and durability quartz offers. If you see what you love, you can work with our team to schedule the installation of your new countertops.