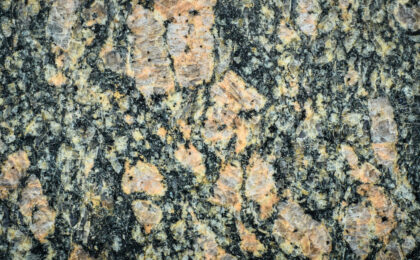

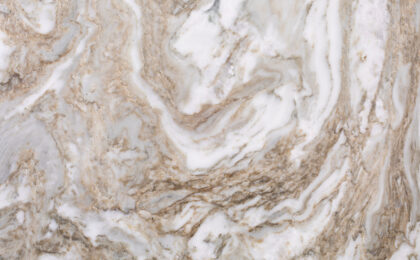

Stone countertops are a beautiful addition to any kitchen. Materials like granite, marble, and quartzite can make an already beautiful kitchen absolutely stunning. But whenever you are working with natural stone, you need to ensure that installation is done correctly. That includes the use of structural supports.

Proper structural support is critical for materials like granite and marble because of their weight. In addition, natural stone countertops are susceptible to stress fractures due to a combination of weight and brittleness. Without proper structural support, that beautiful stone countertop you paid dearly for might not look so beautiful a few years down the road.

Unsupported Overhangs

Structural support ensures integrity across the entire surface of a stone countertop. Where there are unsupported overhangs, installers need to be careful about how much material they are dealing with. Generally speaking, an unsupported overhang should not exceed one-third of the total countertop width. So on a countertop that is 36 inches wide, any unsupported overhang should not be greater than 12 inches.

You should use a bracket to support any overhang greater than 12 inches. However, there is some flexibility here depending on the thickness of the slab. Thicker slabs can handle larger overhangs while thinner slabs may need additional support.

Different Means of Providing Support

Installers have access to different means of providing support. At the top of the list are metal brackets usually installed underneath the countertop, sometimes inside the cabinetry. The primary benefit of this means of support is that metal brackets can be hidden. No one needs to know they are there unless they purposely go looking for them.

Metal brackets are generally spaced 18-24 inches apart. End point braces are usually no further than 4-6 inches from the edge. If metal brackets are unacceptable to the customer, installers have other choices:

- Corbels – Corbels are similar to metal braces but with two exceptions: they are normally attached to walls rather than cabinetry and they are designed to be decorative. Supporting a marble or granite countertop with corbels adds a nice touch.

- Plywood – Thinner slabs are often supported by a plywood base that evenly distributes support across the entire surface. A plywood substrate acts to reinforce the edges as well. Thicker slabs rarely require plywood support.

Ideally, an installer will know the best way to support a stone or marble countertop. One way or the other, proper support is critical to long life and aesthetic integrity.

Preparation Is Key

As with everything related to stone countertops, preparation is key to proper installation. Before countertop installation, you should level and securely anchor the cabinets. This mitigates the risk of putting undue stress on a stone slab.

Where necessary, wall cleats can be attached for additional stability. Wall cleats are mounted on the studs. They are ideal for providing extra support in the corners or underneath exceptionally long spans of countertop surface.

When it comes time to install the support brackets, installers will often use an adhesive along with fasteners. Applying an adhesive prevents shifting as everything gradually settles.

We Install Everything We Sell

If you are considering stone countertops and are worried about proper installation with structural support, rest assured that we install everything we sell. Here at Bedrock Quartz, we do not compromise on quality. Our fully trained and experienced installers will do the job right.Marble and stone countertops do require structural support. But it is no big deal to an experienced installer who has worked with stone before. Support marble and granite properly and it will provide decades of reliable service and incomparable aesthetic beauty.